Service & Support

Rosco is focused on supporting you, our customer and partner, in maintaining your equipment to factory specification, resolving warranty issues and assisting during breakdowns and repairs. We provide Factory Certified Field Service Technicians, Factory Parts, and Applications Engineering Support. We also offer maintenance and calibration services for long-term reliability of your machinery. We understand that performance and quality is vital to the success of your business and ours.

- Factory Trained Service Technicians in Machine Tools and Measuring Instruments

- Warranty Service and Preventative Maintenance

- Factory Parts

- Telephone Support

- Applications Support and Training

Training

In addition to the Training our factory certified technicians provide with every machine sold, we also offer on-line and in-person training classes. Talk with us today to decide the best options for your company.

When you invest in a CNC machine that is as flexible and powerful as the Hurco, the quickest way to achieve maximum benefit is to make sure you have proper training. Self-directed and Instructor led in-person and on-line training classes are available and scheduled weekly.

Instructional Videos and on-line classes available. In-person instruction and lifetime unlimited support comes with every TRAK purchase.

Rosco’s OGP sales representatives have been through rigorous training and are a great first contact for training. If wanted, OGP also offers additional classes at their corporate headquarters.

Maintenance & Repair

Maintenance is an often overlooked part of machine tool & measurement instrument system operation.

At Rosco Precision Machinery, we take a preventative approach to maintenance, staying ahead of breakdowns and unanticipated issues with your equipment so that you can focus on making parts.

TRAK Mill & Lathe Machine Maintenance

We offer a range of maintenance & repair services from Factory Trained Technicians for all TRAK equipment. Plans include:

- Diagnostic service code check

- Gib adjustment as needed

- X,Y,Z and calibration

- Verify accuracy & repeatability

- Spindle check throughout RPM Range

- 25 and 50 point plans available

QVI Optical, Video, & CMM Maintenance

The centerpiece of many QA/QC departments, each of our metrology systems need to maintain the upmost accuracy they’re capable of in order to give reliable results for part inspections over their lifetime. In addition to recommended routine calibrations, Rosco offers repair and preventative maintenance work on systems including:

- Cleaning of system and their workstation including PC controller.

- Cleaning & lubrication of drive screws, drive rods, and XYZ travel rails.

- Troubleshoot & repair of all software errors & hardware issues.

- Verification of accuracy & repeatability.

- Upgrades of systems & controllers including adding additional sensors, such as Laser & Touch Probe.

Calibration

Trust our experienced technicians to keep your equipment performing like new. Rosco Precision Machinery Provides a wide range of services including Calibration, Repair, Maintenance, Retrofits, Training, Support and Warranty for all the products we sell. Rosco Precision Machinery is proud to provide our customers with the best possible and most responsive service available in the industry.

Calibration & Repair

- Video and Multi-sensor Measuring Systems

- ProtoTRAK Milling Machines and Lathes

- HURCO Milling Machines and Lathes

- Preventive maintenance and Scheduled Maintenance

- Optical Comparators

Measuring & Machinery Training & Support

- Video Measuring Systems Software including Zone3, Measure Mind, and Measure X

- Optical Comparator DROs & Software

- Prolink QC-Calc & EVOLVE SPC Software

- HURCO Winmax

- ProtoTRAK Software

- FeatureCAM

Contract Inspection & Reverse Engineering

- Coordinate measuring machines

- Video and non-contact measuring systems

- Laser scanning

Video Measurement and Comparator Calibration

Trust our experienced technicians to keep your equipment performing like new. Calibration and Preventative Maintenance of all critical machine components to assure mechanical and optical accuracy of stage travel to within original manufacturer’s specifications. Included with service:

- Cleaning & lubrication of machine and workstation

- Mechanical alignment of video & optical components

- All lens calibrations

- All additional sensor calibrations including touch probes, lasers, 4thaxis rotaries, etc.

- Software compensations for stage scales

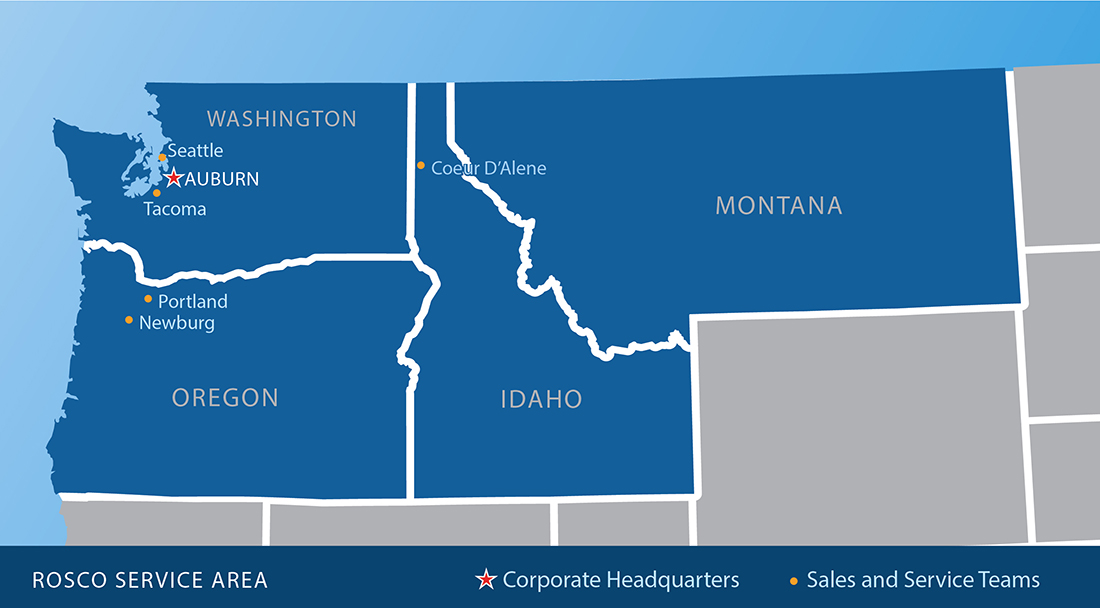

Contact Rosco Precision Machinery for Metrology Equipment and Support in Oregon as well.