Milling Machines

select a machine type

3 Axis Boxway

SMEC HYST 6700

Hybrid Machining Center (X/Y axis LM Guide, Z axis Box guide). Z- Axis Box Guide enhances rigidity and enables heavy duty cutting. X/Y Axis LM guide improve travel precision and significantly reduces non-cutting time.

TAKUMI V Series Boxway VMC

VC Series vertical machining centers are fast, three-axis linear guide machining centers designed for high accuracy molds or production work with demanding surface finish and accuracy requirements. ACII, look ahead and memory standard. Fast Rapids + High Precision

3 Axis Vertical Mills - VMC

TRAK VMC Si Series Performance VMC

TRAK Machine Tools is the first in the USA to offer the Siemens SINUMERIK ONE Control. Innovation and performance in a competitively priced package.

TAKUMI VC – VMCs Fanuc Control

VC Series vertical machining centers are fast, three-axis linear guide machining centers designed for customers doing batch or production work. Fast Rapids + High Precision

HURCO VMX Performance VMC

The VMX Series is Hurco’s signature line of machining centers with impressive standard features and long-lasting durability. Heavy castings and powerful spindles for performance cutting and high- speed machining. Sizes up to 84” in X and 34” in Y. The VMX was created specifically to take advantage of Hurco’s powerful WINMAX Control, fast feeds and 10,000 block look ahead. Machine options include direct drive, HSK 63A and High Torque spindles, expanded ATC and production-enhancing software.

HURCO VM Series General Purpose Machining Centers VMC

The VM Series offers the smallest footprint with huge working area. Designed to make money – low base price and the industry’s most powerful control make the VM series the best value CNC on the market. Standard features include high speed machining, 12K spindles, huge memory and the fastest processing time.

SMEC MCV 5700L (12K) DIRECT

3 Axis LM Guide Type Vertical Machining Center. Largest in class X-axis travel and table with low-center of gravity design.

- Largest in class X-axis travel of 41.34inch

- Largest in class table size of 51.19 × 22.45inch

- Easy user accessibility with a table surface height of 35.43inch

- With 4 rows of Roller LM-Guides in the Y-axis, overhang is prevented

- High strength and high precision with the highly rigid saddle and arched column design

- Maximized space efficiency with the compact design

SMEC MCV 5500 (12K) DIRECT

High Speed And Precision Vertical Machining Center / High Rigidity Structure

- Low centered one piece Bed with triangle Rib design

- Biggest X axis stroke(2,100mm) and table in its class

- Realizing high rigidity and precision with high rigidity Saddle and Column structure

- 2 raws Y axis linear guide way preventing overhang

- High speed and precision direct spindle

SMEC MCV 4300 (12K) DIRECT

High Speed And Precision Vertical Machining Center / High Rigidity Structure

- Low centered one piece Bed with triangle Rib design

- Biggest X axis stroke(2,100mm) and table in its class

- Realizing high rigidity and precision with high rigidity Saddle and Column structure

- 2 raws Y axis linear guide way preventing overhang

- High speed and precision direct spindle

SMEC PCV 430 (10K) DIRECT w/CC

Designed for high speed and ultra precision machining

- The largest machining capacity in its class

- Low centered base structure and rigid one-piece cast iron bed

- The widest guide way span and Saddle in its class

TAKUMI V Series Boxway VMC

VC Series vertical machining centers are fast, three-axis linear guide machining centers designed for high accuracy molds or production work with demanding surface finish and accuracy requirements. ACII, look ahead and memory standard. Fast Rapids + High Precision

3 Axis Double Column

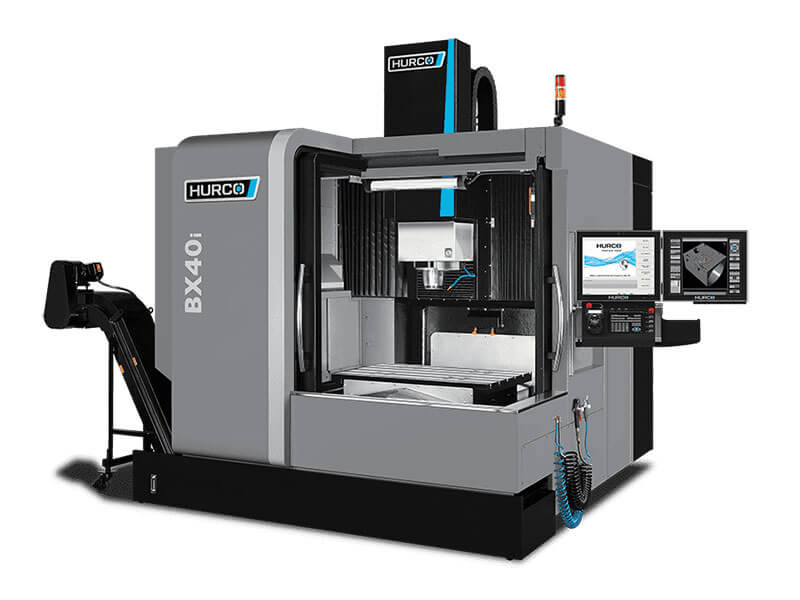

HURCO BX Double Column VMC

The stability of the double-column, the ladder design of the Z-axis, and the overall weight of the BX high-speed milling machines provide exceptional accuracy, thermal compensation, and outstanding surface finish capabilities. Equipped with an 18,000 rpm HSK 64A spindle and Hurco’s patented UltiMotion technology, the BX series of CNC machines is designed for high speeds and tight tolerances.

TAKUMI H Series Double Column

Designed for parts that require outstanding speed and accuracy, and unparalleled surface finish. The H-Series machines offer an extremely rigid and thermally stable double column design. These three-axis models feature high-speed direct drive spindles with up to 15,000 rpm.

Unrivaled Performance + Accuracy

5 Axis Milling VMC

HURCO U Series

The efficient design of the Hurco 5-axis trunnion table machining centers (U Series) is a key benefit to consider—we use an integrated trunnion table instead of simply sticking a trunnion table on a 3-axis machining center and passing it off as a 5-axis CNC machine. The integrated trunnion table design provides more clearance in the Z-axis compared to other brands.

HURCO VC / VCX Series

The B-axis provides superb undercutting ability with a full 110° in both positive and negative directions. Solid one-piece cast iron frame optimized with both static and dynamic Finite Element Analysis (FEA).

The 5-Axis VC / VCX Series B-axis trunnion style configuration will allow for shorter tools to be utilized when cutting smaller parts. When cutting smaller parts on a traditional A-axis trunnion, the tools approach the part from behind the A-axis trunnion. This means when running smaller 5-Axis parts on larger machines, the operator is forced to use longer tools for clearance. Since a B-axis trunnion tilts around the Y-axis, the tool is always approaching the part from a safe direction and the possibility for interference is much less.

HURCO SRT Series

The SRTi series of 5-axis CNC machines offers multiple advantages, starting with the machine’s design configuration that utilizes a B Axis swivel head and a C-axis rotary torque table that is embedded in the machine table and flush with the surface. The generous size of the machine table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis CNC work. This configuration is also available in an SW model that utilizes the B Axis swivel head, traditional machine table, and an add-on A-axis rotary.

Hurco BX Series

The stability of the double-column, the ladder design of the Z-axis, and the overall weight of the BX high-speed milling machines provide exceptional accuracy, thermal compensation, and outstanding surface finish capabilities. Equipped with an 18,000 rpm HSK 64A spindle and Hurco’s patented UltiMotion technology, the BX series of CNC machines is designed for high speeds and tight tolerances.

HURCO DCX Series

The DCX Series of Double Column CNC machining centers were created due to customer requests—customers who already knew the value of Hurco and needed larger machines for aerospace and energy parts. Our 2-meter, 3-meter, and 4-meter VMCs are the biggest machine tools available with the powerful Hurco control.

TAKUMI U Series

Takumi CNC machines are designed for superior speed, quality finish, and the accuracy needed for today’s aerospace industry.

MVF 5000 (12K) DIRECT

- Fine grain one-piece Meehanite® cast iron bed

- Rigid triangular rib body structure for minimizing vibration and deformation under heavy machining

- Anti-heat displacement spindle and headstock design

- Ultra-precision and high rigidity spindle bearings

- Wide and heavy-duty cross roller guide ways

- High precision pre-tensioned large diameter ball screws for all axes

- Powerful and reliable Fanuc motors and drives system

- Automatic lubrication through metered piston distributor

5 Axis Gantry

TAKUMI U Series

Takumi CNC machines are designed for superior speed, quality finish, and the accuracy needed for today’s aerospace industry.

Toolroom Mills

TRAK TMC TOOLROOM Machining Centers

A versatile Toolroom VMC machine that works the way you want. Manual, 2 Axis, 3 Axis. Fully enclosed with a 16 position ATC. Full range of sizes up to 60 inches in X.

TRAK TOOLROOM BEDMILLS

The Best Machines Ever Made for Toolroom and Short Run Production.

- Manual with DRO, 2 or 3 axis CNC

- Programmable spindle speeds

- Real handwheels so you can work manually

- Integrated Ram along with quill and scale!

TRAK TOOLROOM Kneemill

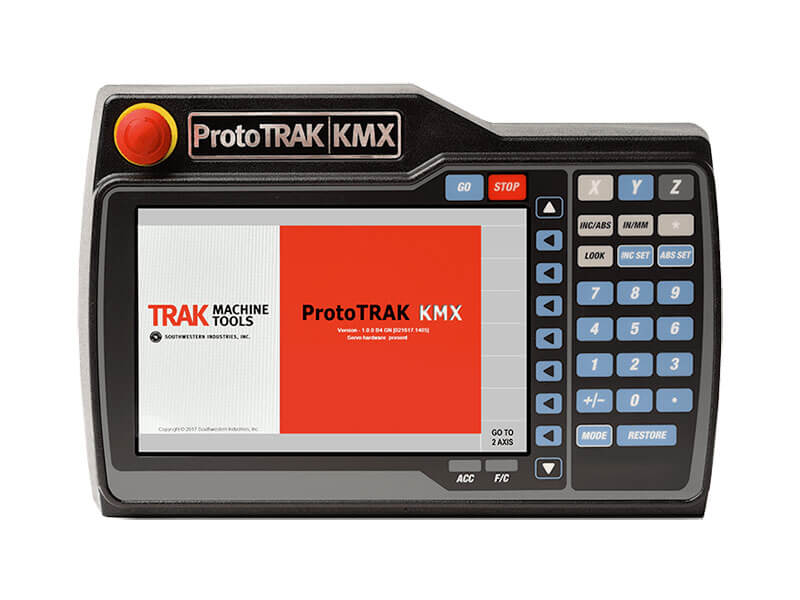

TRAK toolroom mills are equipped with the easiest to use control on the market – the ProtoTRAK CNC.

The ProtoTRAK CNC is designed specifically for prototype, one-off and small lot machining. All TRAK toolroom mills can operate manually with DRO, or 2 or 3 axis CNC.

TRAK CNC RETROFITS

Make your manual machines more productive.

TRAK has transformed thousands of Bridgeport® and similar knee-type milling machines from outdated manual machines to highly productive ProtoTRAK CNCs. With experience earned over 30 years, TRAK knows how to give you the best possible outcome.

Bridge Mills

HURCO DCX Series

The DCX Series of Double Column CNC machining centers were created due to customer requests—customers who already knew the value of Hurco and needed larger machines for aerospace and energy parts. Our 2-meter, 3-meter, and 4-meter VMCs are the biggest machine tools available with the powerful Hurco control.

Horizontal

TAKUMI HMX Series

Takumi horizontal machining centers are built for speed. With up to 1G acceleration, fast rapids and feed rates, quick spindle acceleration/deceleration, swift pallet indexing and exchange, Takumi horizontals are designed to help you make better parts faster.

HURCO HM SERIES

These economical, 3-axis and 4-axis large travel horizontal CNC milling machines have an 8,000 rpm motorized spindle that is equipped for both high and low-end torque operations. The large, front and side access doors provide maximum operator efficiency. With fast rapids, large work cube, smart frame design, and UltiMotion technology, complex production parts can be CNC machined efficiently and accurately. Hurco’s horizontal milling machines increase shop productivity with a rotary torque table, such as the table added to the smart design of the HM1700i CNC machining center.

HURCO HBMX Series

The HBMX horizontal boring machines have 2-speed geared-head spindles, hardened box ways, and they are packaged to include features needed for typical applications—such as a programmable quill that allows you to use shorter tools, a contouring 4th axis rotary table (not just positional), linear glass scales to maintain thermal stability and increase accuracy, CTS, and a 60-tool ATC.

Manual Mills

TRAK Toolroom

The Best Machines Ever Made for Toolroom and Short Run Production.

- Manual with DRO, 2 or 3 axis CNC

- Programmable spindle speeds

- Real handwheels so you can work manually

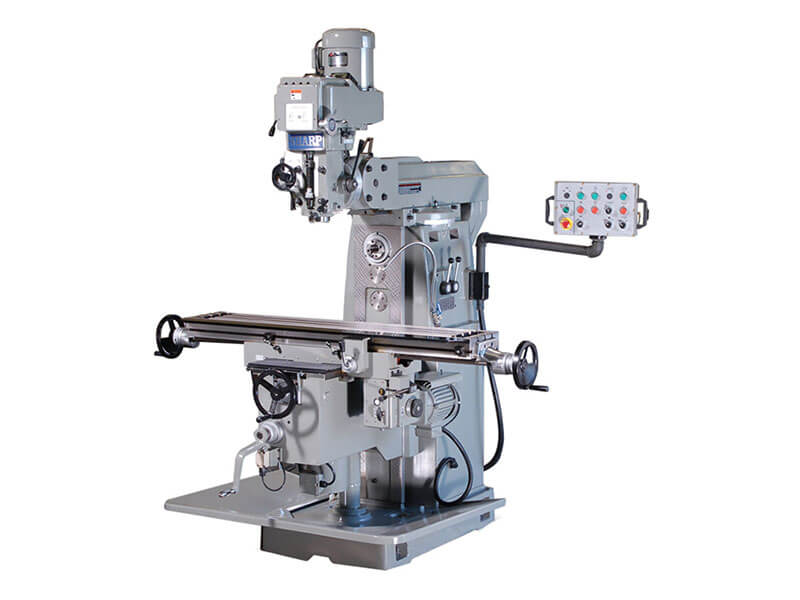

SHARP Kneemills

Sharp manual knee mills are built with the highest quality standards. Add a 2 axis or 3 axis DRO or CNC retrofit for easy and economical CNC Milling.

Acer Kneemills

Acer E-mill™ Series milling machines are “trouble free” mills. Add a DRO or a CNC retrofit of your choice.

TRAK CNC RETROFITS

Make your manual machines more productive.

TRAK has transformed thousands of Bridgeport® and similar knee-type milling machines from outdated manual machines to highly productive ProtoTRAK CNCs. With experience earned over 30 years, TRAK knows how to give you the best possible outcome.

Automation

ER Work

A mobile and low cost collaborative robot cell for CNC machine tending and lights out machining.

ProFeeder

ProCobot’s ProFeeder series, integrated with a collaborative robot arm from Universal-Robots, enables factories to implement a standardized Robot Cell that’s movable inside the factory, taking the hassle out of integrating and designing a customized robotics cell. The ProFeeder system is a flexible and scalable solution that’s easy to setup and convert to new jobs. ProFeeder PF Plus software is built around a database of trays, tools and part configurations. This eliminates the need to program the Universal Robot when changing jobs.

ProFeeder X

- 5 or 10 drawer systems available

- 3-position drawers for continuous production

- High capacity with compact footprint