Milling Machines

3 Axis Vertical Mills - VMC

TRAK VMC Si Series Performance VMC

TRAK Machine Tools is the first in the USA to offer the Siemens SINUMERIK ONE Control. Innovation and performance in a competitively priced package.

5 Axis Milling VMC

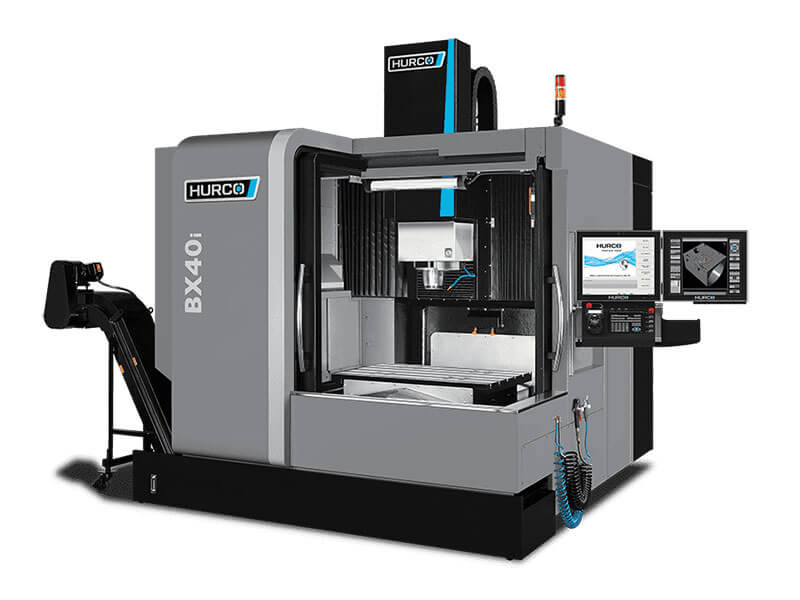

HURCO VC / VCX Series

The B-axis provides superb undercutting ability with a full 110° in both positive and negative directions. Solid one-piece cast iron frame optimized with both static and dynamic Finite Element Analysis (FEA).

The 5-Axis VC / VCX Series B-axis trunnion style configuration will allow for shorter tools to be utilized when cutting smaller parts. When cutting smaller parts on a traditional A-axis trunnion, the tools approach the part from behind the A-axis trunnion. This means when running smaller 5-Axis parts on larger machines, the operator is forced to use longer tools for clearance. Since a B-axis trunnion tilts around the Y-axis, the tool is always approaching the part from a safe direction and the possibility for interference is much less.

HURCO SRT Series

The SRTi series of 5-axis CNC machines offers multiple advantages, starting with the machine’s design configuration that utilizes a B Axis swivel head and a C-axis rotary torque table that is embedded in the machine table and flush with the surface. The generous size of the machine table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis CNC work. This configuration is also available in an SW model that utilizes the B Axis swivel head, traditional machine table, and an add-on A-axis rotary.

HURCO U Series

The efficient design of the Hurco 5-axis trunnion table machining centers (U Series) is a key benefit to consider—we use an integrated trunnion table instead of simply sticking a trunnion table on a 3-axis machining center and passing it off as a 5-axis CNC machine. The integrated trunnion table design provides more clearance in the Z-axis compared to other brands.

5 Axis Gantry

Sorry, we couldn't find any products.

Toolroom Mills

TRAK TOOLROOM BEDMILLS

The Best Machines Ever Made for Toolroom and Short Run Production.

- Manual with DRO, 2 or 3 axis CNC

- Programmable spindle speeds

- Real handwheels so you can work manually

- Integrated Ram along with quill and scale!

TRAK TOOLROOM Kneemill

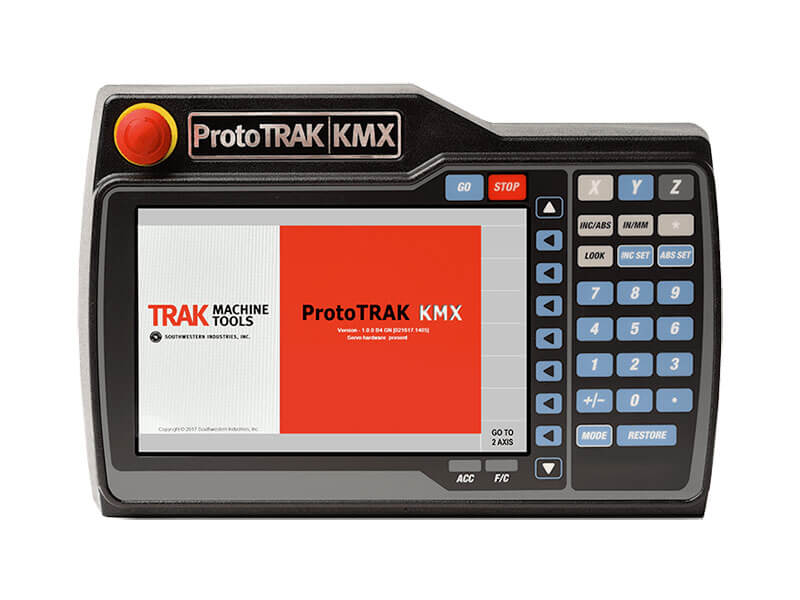

TRAK toolroom mills are equipped with the easiest to use control on the market – the ProtoTRAK CNC.

The ProtoTRAK CNC is designed specifically for prototype, one-off and small lot machining. All TRAK toolroom mills can operate manually with DRO, or 2 or 3 axis CNC.

TRAK CNC RETROFITS

Make your manual machines more productive.

TRAK has transformed thousands of Bridgeport® and similar knee-type milling machines from outdated manual machines to highly productive ProtoTRAK CNCs. With experience earned over 30 years, TRAK knows how to give you the best possible outcome.

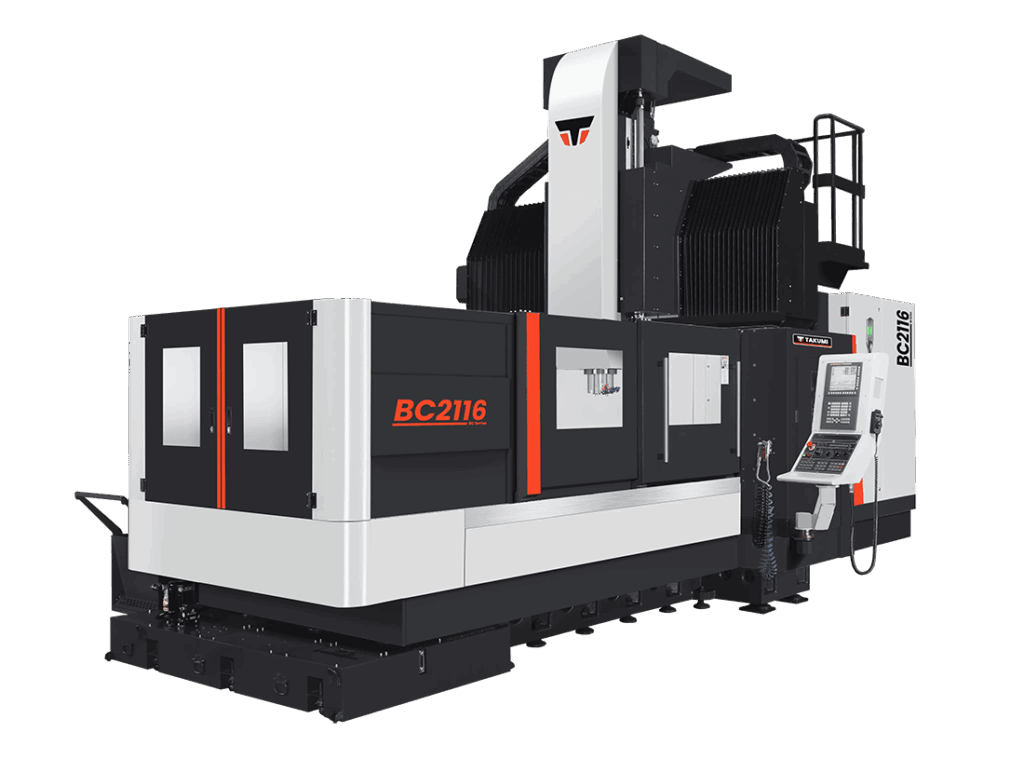

Bridge Mills

Horizontal

HURCO HBMX Series

The HBMX horizontal boring machines have 2-speed geared-head spindles, hardened box ways, and they are packaged to include features needed for typical applications—such as a programmable quill that allows you to use shorter tools, a contouring 4th axis rotary table (not just positional), linear glass scales to maintain thermal stability and increase accuracy, CTS, and a 60-tool ATC.

HURCO HM SERIES

These economical, 3-axis and 4-axis large travel horizontal CNC milling machines have an 8,000 rpm motorized spindle that is equipped for both high and low-end torque operations. The large, front and side access doors provide maximum operator efficiency. With fast rapids, large work cube, smart frame design, and UltiMotion technology, complex production parts can be CNC machined efficiently and accurately. Hurco’s horizontal milling machines increase shop productivity with a rotary torque table, such as the table added to the smart design of the HM1700i CNC machining center.

Manual Mills

TRAK Toolroom

The Best Machines Ever Made for Toolroom and Short Run Production.

- Manual with DRO, 2 or 3 axis CNC

- Programmable spindle speeds

- Real handwheels so you can work manually

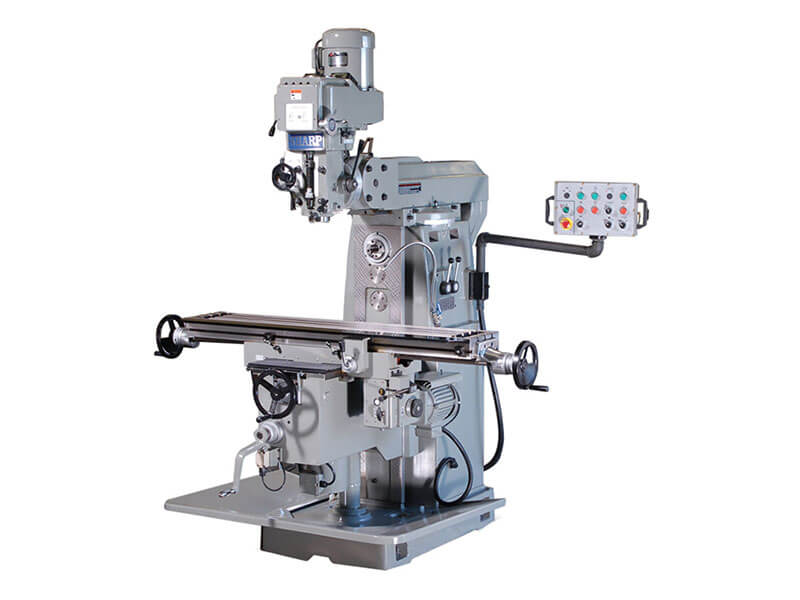

SHARP Kneemills

Sharp manual knee mills are built with the highest quality standards. Add a 2 axis or 3 axis DRO or CNC retrofit for easy and economical CNC Milling.

Acer Kneemills

Acer E-mill™ Series milling machines are “trouble free” mills. Add a DRO or a CNC retrofit of your choice.

TRAK CNC RETROFITS

Make your manual machines more productive.

TRAK has transformed thousands of Bridgeport® and similar knee-type milling machines from outdated manual machines to highly productive ProtoTRAK CNCs. With experience earned over 30 years, TRAK knows how to give you the best possible outcome.

Automation

HURCO VC / VCX Series

The B-axis provides superb undercutting ability with a full 110° in both positive and negative directions. Solid one-piece cast iron frame optimized with both static and dynamic Finite Element Analysis (FEA).

The 5-Axis VC / VCX Series B-axis trunnion style configuration will allow for shorter tools to be utilized when cutting smaller parts. When cutting smaller parts on a traditional A-axis trunnion, the tools approach the part from behind the A-axis trunnion. This means when running smaller 5-Axis parts on larger machines, the operator is forced to use longer tools for clearance. Since a B-axis trunnion tilts around the Y-axis, the tool is always approaching the part from a safe direction and the possibility for interference is much less.

HURCO SRT Series

The SRTi series of 5-axis CNC machines offers multiple advantages, starting with the machine’s design configuration that utilizes a B Axis swivel head and a C-axis rotary torque table that is embedded in the machine table and flush with the surface. The generous size of the machine table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis CNC work. This configuration is also available in an SW model that utilizes the B Axis swivel head, traditional machine table, and an add-on A-axis rotary.

HURCO U Series

The efficient design of the Hurco 5-axis trunnion table machining centers (U Series) is a key benefit to consider—we use an integrated trunnion table instead of simply sticking a trunnion table on a 3-axis machining center and passing it off as a 5-axis CNC machine. The integrated trunnion table design provides more clearance in the Z-axis compared to other brands.

HURCO HBMX Series

The HBMX horizontal boring machines have 2-speed geared-head spindles, hardened box ways, and they are packaged to include features needed for typical applications—such as a programmable quill that allows you to use shorter tools, a contouring 4th axis rotary table (not just positional), linear glass scales to maintain thermal stability and increase accuracy, CTS, and a 60-tool ATC.

HURCO HM SERIES

These economical, 3-axis and 4-axis large travel horizontal CNC milling machines have an 8,000 rpm motorized spindle that is equipped for both high and low-end torque operations. The large, front and side access doors provide maximum operator efficiency. With fast rapids, large work cube, smart frame design, and UltiMotion technology, complex production parts can be CNC machined efficiently and accurately. Hurco’s horizontal milling machines increase shop productivity with a rotary torque table, such as the table added to the smart design of the HM1700i CNC machining center.